Common Problems in CNC Machining and Their Solutions:

- Poor surface finish: This issue can arise due to incorrect tool selection, improper cutting parameters, or worn-out cutting tools. The solutions include choosing the appropriate tool, optimizing cutting parameters (such as speed, feed rate, and depth of cut), and regularly inspecting and replacing worn-out tools.

- Dimensional inaccuracies: CNC machining may result in parts with dimensions that deviate from the required specifications. To address this problem, it is essential to ensure proper machine calibration, use accurate machining programs, and regularly check and maintain the machine's accuracy.

- Tool breakage: Tool breakage can occur due to excessive cutting forces, improper tool paths, or worn-out tools. To prevent tool breakage, it is necessary to optimize tool paths, use high-quality cutting tools, and monitor machining conditions to avoid excessive cutting forces.

- Chip evacuation problems: Chips generated during machining may get trapped in the cutting area, leading to poor machining quality and tool damage. To enhance chip evacuation, suitable cutting parameters should be applied, and chip removal methods such as coolant or compressed air can be employed.

- Thermal deformation: The heat generated during machining can cause thermal expansion and result in workpiece or tool deformation, leading to dimensional errors. Minimizing thermal deformation involves using cutting fluids, implementing proper cooling techniques, and considering the use of tool coatings or materials with higher thermal stability.

- Machine tool vibration: Vibration can negatively impact machining accuracy and surface finish. To mitigate machine tool vibration, it is necessary to ensure proper machine installation, use high-quality cutting tools, optimize cutting parameters, and implement vibration damping techniques.

- Material selection and compatibility: Choosing the right material for CNC machining is crucial to avoid issues such as poor machinability, tool wear, or surface defects. Conducting material testing, consulting material suppliers, and considering the material's properties and machining guidelines can help address these challenges.

Q1:

How to address the issue of poor dimensional accuracy in workpieces?

A1: Causes and strategies to address poor dimensional accuracy in workpieces:

Tool wear: Tool wear can result in changing cutting forces, which in turn affects the dimensional accuracy of workpieces.

Strategy: Regularly inspect and replace worn-out tools to ensure that the tools maintain good cutting conditions.

Machine tool thermal deformation: Machine tools can experience thermal expansion or deformation during operation, leading to dimensional deviations in workpieces.

Strategy: Control the temperature of the machine tool and implement cooling measures, such as using coolant or installing a cooling system, to reduce the impact of thermal deformation.

Inaccurate machining parameters: Incorrectly set machining parameters such as feed rate and cutting depth can affect the dimensional accuracy of workpieces.

Strategy: Set appropriate machining parameters based on material properties, tool types, and machining requirements. Conduct trial cutting tests and adjust the parameters to find the optimal machining conditions.

Q2:

How to address the issue of poor surface finish?

A2: Causes and strategies to address poor surface finish:

Improper cutting parameters: Incorrectly set cutting parameters, such as excessive feed rate or high rotational speed, can result in poor surface finish.

Strategy: Optimize cutting parameters by reducing the feed rate, adjusting the rotational speed appropriately, and ensuring proper chip evacuation to improve surface finish.

Tool wear or edge damage: Tool wear or edge damage can cause irregular cutting and affect surface quality.

Strategy: Regularly inspect and replace worn-out tools to maintain a sharp cutting edge. Use high-quality tools to enhance cutting performance.

Improper cutting fluid: Improper selection and usage of cutting fluids can result in poor lubrication or inadequate cooling, affecting surface finish.

Strategy: Choose cutting fluids that are suitable for the machining material and tools. Follow the recommended guidelines for their usage and ensure proper maintenance and replacement of the fluids.

Q3:

Causes and strategies to address the issue of workpiece taper in CNC machining:

A3:In CNC (computer numerical control) processing, the phenomenon of the size of the workpiece is usually caused by one of the following reasons:

Imbalanced cutting forces: Uneven distribution of cutting forces during machining can result in workpiece taper.

Strategy: Adjust cutting parameters such as feed rate, cutting depth, etc., to achieve a more balanced distribution of cutting forces. If possible, consider using multiple cutting tools to balance the cutting forces.

Tool wear or edge damage: Tool wear or edge damage can cause uneven cutting, leading to workpiece taper.

Strategy: Regularly inspect and replace worn-out tools to maintain a good cutting condition. Use high-quality tools and ensure proper tool installation and adjustment.

Machine tool thermal deformation: Thermal expansion or deformation of the machine tool during operation can cause workpiece taper.

Strategy: Control the temperature of the machine tool and implement cooling measures such as using coolant or installing a cooling system to reduce the impact of thermal deformation. When machining high-precision workpieces, consider using temperature compensation features if available.

Uneven clamping force: Uneven distribution of clamping force on the workpiece can result in workpiece taper.

Strategy: Adjust the clamping force distribution on the fixture to ensure even clamping. Use appropriate fixtures and clamping methods to maintain a stable position of the workpiece during machining.

Q4:

How to address the issue of inconsistent workpiece dimensions in CNC machining?

A4: If the phase lights of the CNC machine are functioning properly but the dimensions of the machined workpiece are inconsistent, it may be caused by one of the following reasons:

Uneven tool wear or edge damage: Non-uniform tool wear or edge damage can result in uneven distribution of cutting forces, leading to inconsistent workpiece dimensions.

Strategy: Regularly inspect and replace worn-out tools to maintain a good cutting condition. Use high-quality tools and ensure proper tool installation and adjustment.

Inappropriate cutting parameters: Incorrectly set cutting parameters can cause variations in cutting forces, thereby affecting the stability of workpiece dimensions.

Strategy: Optimize cutting parameters such as feed rate, cutting depth, cutting speed, etc., based on material characteristics and machining requirements. Conduct trial cutting tests and adjust the parameters to find the optimal machining conditions.

Machine tool thermal deformation: Thermal expansion or deformation of the machine tool during operation can result in inconsistent workpiece dimensions.

Strategy: Control the temperature of the machine tool and implement cooling measures such as using coolant or installing a cooling system to reduce the impact of thermal deformation. When machining high-precision workpieces, consider using temperature compensation features if available.

Remember that these are general problems and solutions, and the specific issues may vary based on the CNC machine, tools, materials, and machining processes used. Regular maintenance, operator training, and continuous improvement practices are essential to address and prevent problems in CNC machining.

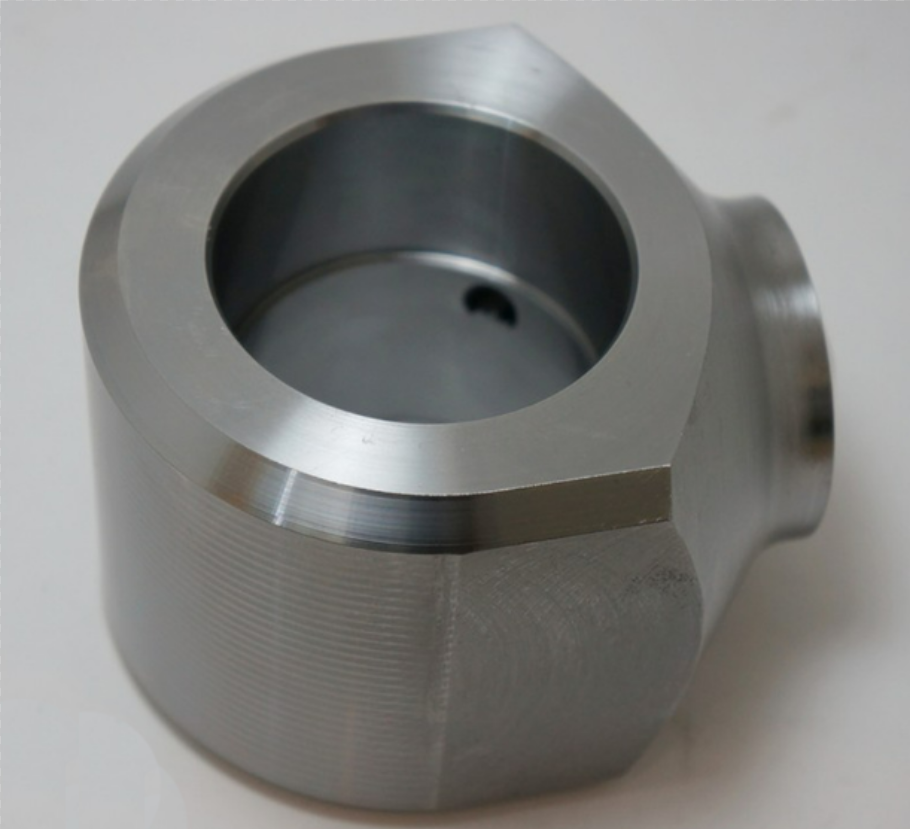

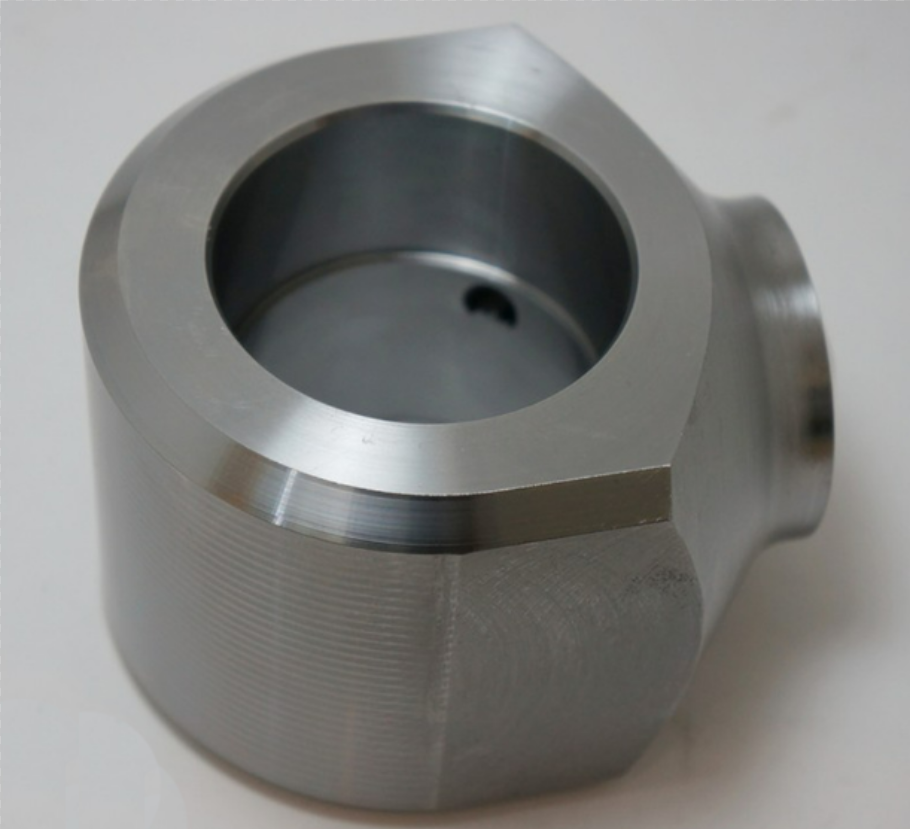

Justway's "hard strengths" in CNC machining technology:

CNC machining technology is widely used in the manufacturing industry, and Justway utilizes CNC machines primarily for metal parts machining and rapid mold machining. The raw materials used for machining include metal materials such as 45# steel, 6061T6 aluminum alloy, 7075 aluminum alloy, zinc alloy, magnesium alloy, and brass. The machining process involves using excavating, cutting, and specialized milling tools on block-shaped materials. Justway works with customer-provided 3D data drawings and utilizes CNC machining methods, including rapid prototyping through CNC milling, to transform metal block materials into metal samples and small-batch components that match the drawings. Justway specializes in small-batch customization, accepting file-based sampling production. You can trust Justway for your CNC machining needs!

3D Printing

3D Printing

Automotive

Automotive

Electrical

Electrical

Energy and Power

Energy and Power

Industrial Design

Industrial Design

Just for Fun

Just for Fun

Medical

Medical

Robotics

Robotics

Tech

Tech

Tools

Tools